रà¥à¤«à¥à¤°à¤¿à¤à¥à¤°à¥à¤à¥à¤¡ à¤à¤¾à¤à¤ª डà¥à¤°à¤¾à¤¯à¤°

Price 32000 आईएनआर/ Unit

रà¥à¤«à¥à¤°à¤¿à¤à¥à¤°à¥à¤à¥à¤¡ à¤à¤¾à¤à¤ª डà¥à¤°à¤¾à¤¯à¤° Specification

- उपयोग

- औद्योगिक उपयोग के लिए

- पावर सोर्स

- इलेक्ट्रिक

- स्नेहन का प्रकार

- ऑयल-लेस

- प्रॉडक्ट टाइप

- ड्रायर

- वोल्टेज

- 220 - 240 वोल्ट (v)

- रंग

- सफेद और नारंगी

- वारंटी

- 1 वर्ष

रà¥à¤«à¥à¤°à¤¿à¤à¥à¤°à¥à¤à¥à¤¡ à¤à¤¾à¤à¤ª डà¥à¤°à¤¾à¤¯à¤° Trade Information

- Minimum Order Quantity

- 1 Unit

- आपूर्ति की क्षमता

- 1 प्रति दिन

- डिलीवरी का समय

- 1 दिन

- पैकेजिंग का विवरण

- लकड़ी का बक्सा

- मुख्य घरेलू बाज़ार

- ऑल इंडिया

About रà¥à¤«à¥à¤°à¤¿à¤à¥à¤°à¥à¤à¥à¤¡ à¤à¤¾à¤à¤ª डà¥à¤°à¤¾à¤¯à¤°

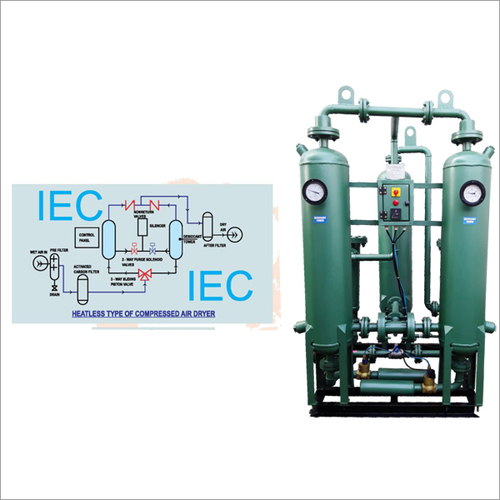

Refrigerated Type Dryer

Cooling is the simplest and most positive way of removing moisture from compressed Air. A Refrigerated Dryer has closed-loop Freon circuit, which cools compressed air to a controlled temperature and so condensed moisture is separated out. To prevent freezing of condensed moisture in the heat exchanger, Air/Gas, can be cooled to a minimum temperature of +2-30C approx i.e. the dew point of dried fluid at operating pressure 7 kgf/Cm2g is (+) 20C and its corresponding atmospheric dew point would be (-) 220C (approx). These dryers are suitable for the applications where the maximum dew point of (-) 20 to (-) 220C (Atm.) is normally acceptable.

Compressed Air Dryers

Moisture Use Air / Gas Dryer

Water or Moisture in the compressed air system causes air leakages, damages tools systems and ultimately increases cost.

Problems due to unwanted moisture in the compressed air system

- Rust and scale deposit in steel pipes causes leakages, increase resistance to flow.

- Malfunctioning of pressure control equipment & instrumentation.

- Corrosion in Solenoid valves & Pneumatic cylinders.

- Solidification of media in pneumatic conveying systems.

- Bubbling or orange peal effect in paint spraying & powder coating.

- Sluggish operation of cylinder, valves & other moving parts.

This results in loss of efficiency & material and increases downtime. Moisture is usually the single major cause of unnecessary costs to compressed air system. The cost of drying air is much lower than the damage. Thus clean, dry compressed air produced using air Dryer is essential for effective pneumatic system.

Technical Specifications:

| APPLICATION | ISO CLASS | DEW PT. | MAX VALUE IN (MG/M3) | DRYER TYPE | |||

| DUST | Oil | R | H | HL | |||

| AGITATION | 5 | +7 | NS | 25 |

|

|

|

| STORAGE AIR | 2 | -40 | 1 | 0.1 |

|

|

|

| MEASURING AIR | 3 | 20 | 5 | 1.0 |

|

|

|

| AIR TURBINES | 2 | w-40 | 1 | 0.1 |

|

|

|

| STONES &GLASS | 3 | -20 | NS | 25 |

|

|

|

| SHOES/LEATHER | 3 | -20 | 5 | 1.0 |

|

|

|

| CLEAN MACH. PARTS | 4 | +7 | NS | 25 |

|

|

|

| GRANULAR SUBS. CONVY. | 4 | +3 | NS | 5 |

|

|

|

| PULVERIZED SUBS. ONVY | 3 | -20 | 5 | 1.0 |

|

|

|

| POWER CIRCUITS | 4 | +3 | NS | 5 |

|

|

|

| FOUNDRY MACHINES | 4 | +3 | NS | 5 |

|

|

|

| FOOD & BEVERAGES | 3 | -20 | NS | 5 |

|

|

|

| MACHINE TOOLS | 3 | -20 | 5 | 1.0 |

|

|

|

| PACK-TEXTILE MACH. | 3 | -20 | 5 | 1.0 |

|

|

|

Water Content conversion chart

| Dew point | PPM weight basis | |

| C | F |

|

| (-) 80 | (-) 112 | 00.33 |

| (-) 60 | (-) 076 | 06.59 |

| (-) 40 | (-) 040 | 78.90 |

| (-) 20 | (-) 04 | 00633 |

| 00 | (+) 32 | 03640 |

| (+) 18 | (+) 64 | 12650 |

FAQs of Refrigerated Type Dryer:

Q: What is the power source for the Refrigerated Type Dryer?

A: The power source for the Refrigerated Type Dryer is Electric.Q: What is the lubrication type used in the Refrigerated Type Dryer?

A: The Lubrication Type for the Refrigerated Type Dryer is Oil-less.Q: What is the color of the Refrigerated Type Dryer?

A: The color of the Refrigerated Type Dryer is White & Orange.Q: What is the intended usage of the Refrigerated Type Dryer?

A: The Refrigerated Type Dryer is designed for Industrial Use.Q: What is the warranty period for the Refrigerated Type Dryer?

A: The Refrigerated Type Dryer comes with a warranty of 1 Year.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in संपीड़ित वायु ड्रायर Category

हीटलेस एड्सॉर्प्शन टाइप ड्रायर

उपयोग : औद्योगिक उपयोग के लिए

वारंटी : 1 वर्ष

मूल्य की इकाई : यूनिट/यूनिट

प्रॉडक्ट टाइप : सोखना प्रकार ड्रायर

मूल्य या मूल्य सीमा : आईएनआर

स्नेहन का प्रकार : ऑयललेस

जांच भेजें

जांच भेजें

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें