Heatless Adsorption Type Dryer

Product Details:

- Usage For Industrial Use

- Product Type Adsorption Type Dryer

- Color Green

- Power Source Electric

- Lubrication Type Oil-less

- Voltage 220 - 240 Volt (v)

- Warranty 1 Year

- Click to View more

Heatless Adsorption Type Dryer Price And Quantity

- 1 Unit

- 32000 INR/Unit

Heatless Adsorption Type Dryer Product Specifications

- Green

- Adsorption Type Dryer

- Oil-less

- Electric

- 1 Year

- For Industrial Use

- 220 - 240 Volt (v)

Heatless Adsorption Type Dryer Trade Information

- 1 Unit Per Day

- 1 Days

- Wooden Box

- All India

Product Description

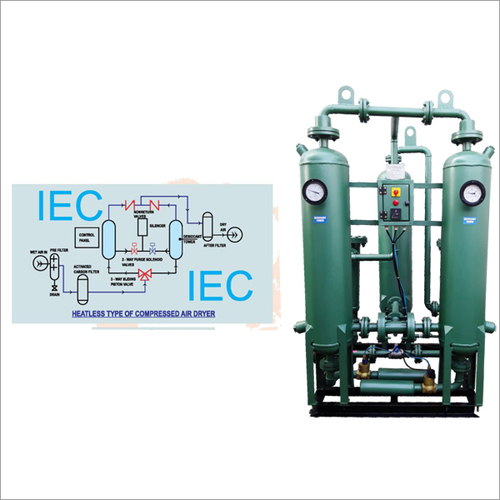

Heatless Adsorption Type Dryer

Heatless type Dryer takes advantage of the natural phenomenon of desiccant to establish equilibrium with their surroundings. In this type, wet Air (fluid) is cycled automatically between two desiccant towers, one adsorbing the moisture from the wet fluid, while the other being regenerated. The wet fluid enters one tower, passes through the desiccant bed where the saturated moisture is adsorbed. A small portion of the dried air at ambient temperature and pressure is passed through the desiccant bed in the second tower for regeneration and is purged to atmosphere. At preset interval, the towers changeover automatically and the cycle continues giving out a regular supply of super dry Air having dew points up to (-) 70C to (-) 80C (At atm. pressure).

Dew point is the measure of moisture content in air. It is the temperature at which moisture content present in the air, starts condensing. Lower the dew point, more dry is the air. Air of (-) 40C Dew Point means no moisture would condense unless temperature of the compressed air is reduced less than (-) 40C. Lower the Dew Point, higher would be the operating cost of Air Dryer. Hence proper selection of Dew point is very important for economical operation of the unit.

Salient Features of IEC Air/Gas Dryer

- Fully automatic push button start equipment. No operator required.

- Dew Point up to (-) 800C can be achieved.

- Soft Seated imported control valves used for bubble tight shut down.

- Gradual depressurisation and repressurisation prevents bed attrition.

- Epoxy coated towers from inside.

- Stainless steel desiccant support screen inside tower.

- Low-pressure drop of 2 Psig only.

- Fabricated as per ASME sec. VIII, Div-1 or IS 2825 codes.

- Units fully tested before despatch.

- Stage-Wise inspection involved.

- Modular skid mounted units.

- Quality product, only quality components used.

- Economical.

Our Recommendations:

| Heat less air dryer | Heat of compression dryer |

| Suited up to 5000 Nm3/hr | Suited for more than 300 Nm3/hr. |

| (-) 400C dew point | (-) 700C dew point. |

| Fully automatic | No external heat reqd. |

| Maintenance free | Nil running cost. |

| Lower initial cost | Suited to only non |

| Air purge loss 7% only | lubricated compressors. |

| Refrigerated dryer | Internal heating dryer |

| Most suited for dew | Most suited for dew |

| points up to (-) 200C | points (-) 60 to (-) 800C |

| low operating costs | low purge loss - (only 3%) |

| No purge air loss | Lowest power consumption. |

Details Required for Preparing Proposals

- Following details are required for preparing proposals:

- Air/Gas Flow Rate/Pressure/Temp and compressor Make & Model

- Dew point required / Application.

- Type of compressor - Lubricated / non-lubricated.

- Application of compressed Air/Gas.

- Erection of unit, whether indoors or outdoors